VIDEO ABOUT VERTICAL MACHINING CENTER 1280S

DESCRIPTION OF VERTICAL MACHINING CENTER 1280S

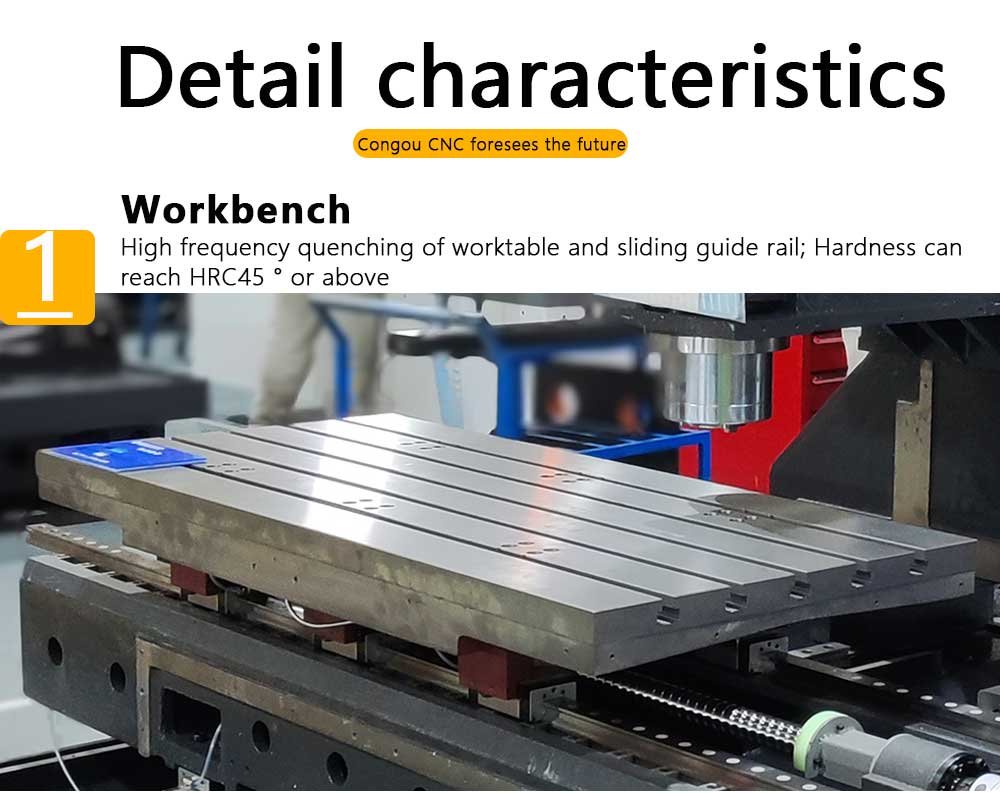

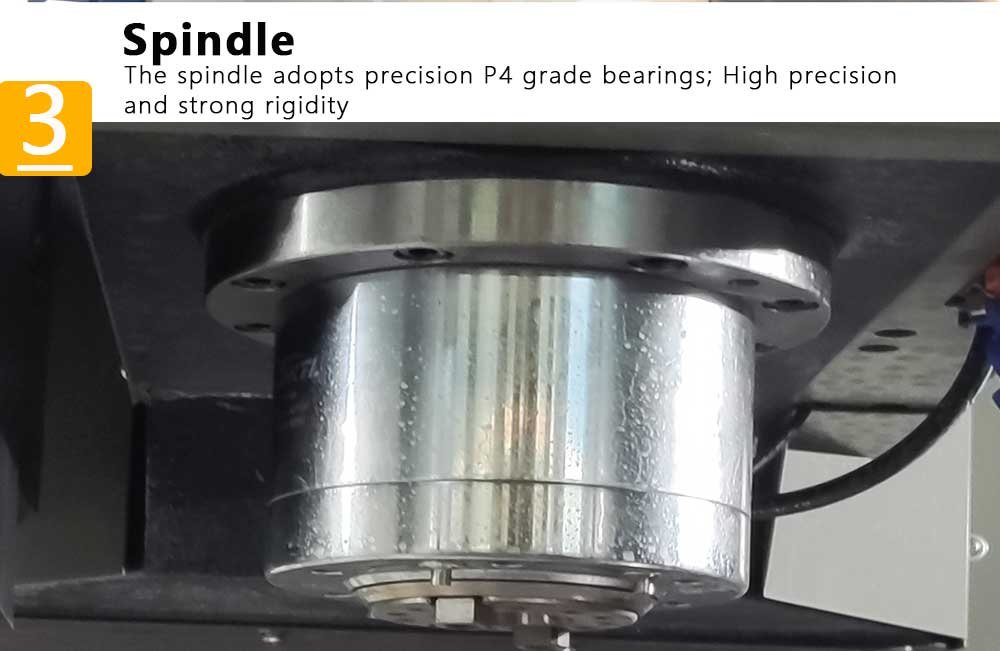

The S series vertical machining center adopts a fixed frame and mobile desktop design, with high main component rigidity and light moving component weight, fully meeting user needs. Milling, boring, drilling, wire cutting, and other processes can be carried out under one clamp. The standard 8000 RPM with spindle has a 1.5:1 reduction and a 50% torque increase. It is suitable for high-speed precision machining of small and medium-sized Machine element in general machinery, automobile, aerospace, textile and other industries. The vertical high-speed machining center series inherits our years of excellent quality and development experience in vertical machining centers, and can provide your customers with faster machining efficiency and higher machining quality.

CHARACTERISTICS OF 1280S

| Model | 1280S |

| Table size | 1300*800mm |

| Maximum load-bearing capacity of the workbench | 800kg |

| X/Y/Z axis coordinate stroke | 700/800/1200mm |

| Distance from the centerline of the spindle to the front guide rail of the column | 850mm |

| Distance from spindle end face to workbench plane | 160-860mm |

| X/Y/Z maximum feed speed | 1-10000mm/min |

| X/Y/Z maximum movement speed | 30/30/24m/min |

| Maximum spindle speed | 6000r/min |

| Spindle taper | BT50-155 |

| Spindle motor power | 11kw |

| T slot(number-width*pitch) | 7-18-110mm |

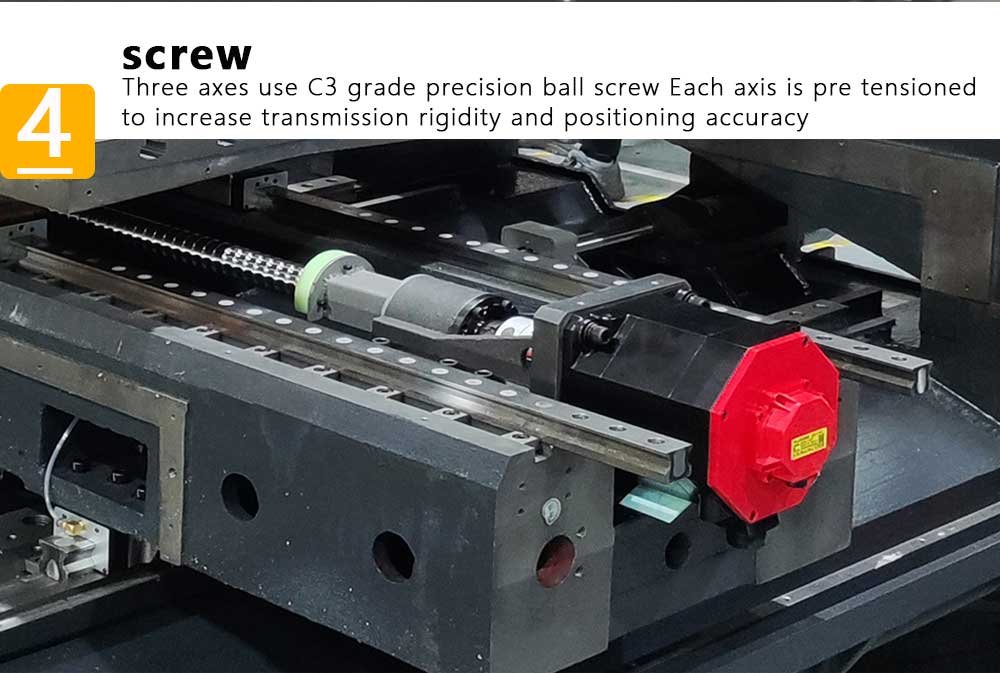

| Positioning accuracy | 0.008mm |

| Repetitive positioning accuracy | 0.006mm |

| Tool magazine form | Bamboo hat style (optional disc) |

| Magazine capacity | 24 |

| Overall dimension | 3010*2380*2680mm |

| Machine weight | 9000kg |