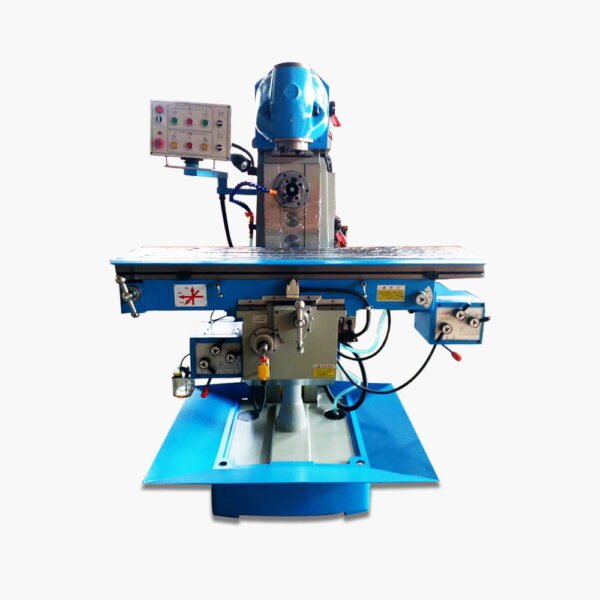

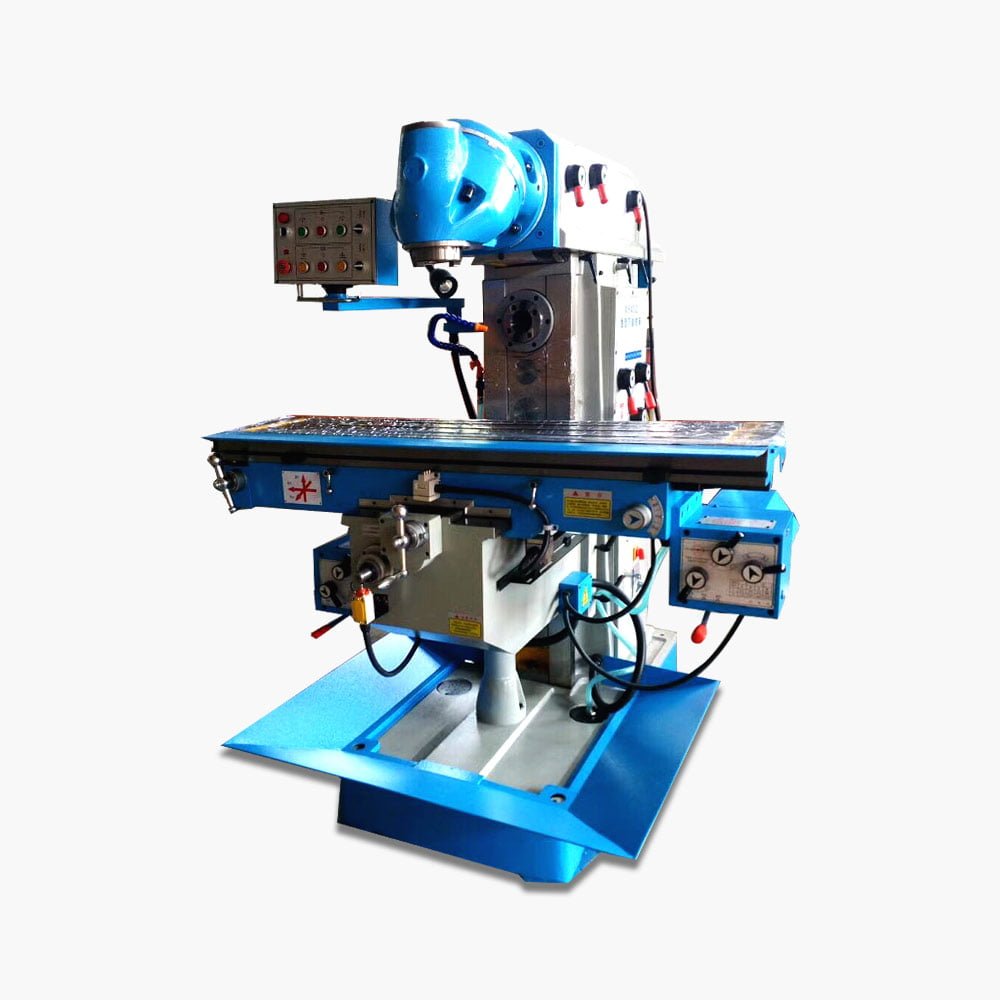

VIDEO ABOUT UNIVERSAL MILLING MACHINE 67A32

DESCRIPTIONS OF UNIVERSAL MILLING MACHINE 67A32

The tool universal milling machine is used for milling workpieces using cylindrical, disc and shaped cutters using a horizontal spindle, and end, end and keyway cutters using a rotary vertical spindle.

The machine allows you to perform milling and boring operations with high accuracy, as well as drilling, reaming, chiseling, centering, caulking, countersinking and deployment operations. The use of the machine is most appropriate at tool sites and in the machine shops of machine-building enterprises of single and small-scale production, as well as in repair departments of enterprises of various fields of activity.

The presence of two horizontal and vertical rotary spindles, as well as a large number of accessories to the machine, makes it widely universal and convenient for working in tool shops of factories in the manufacture of devices, tools, relief stamps and other products.

CHARACRISTICS OF 67A32

| Model | 67A32 |

| Table size | 1320*320mm |

| Number/Width/Distance of T-slot | 3-18-70mm |

| Max.load of table | 500kg |

| Longitudinal travel (manual/auto) (X axis) | 700/680mm |

| Transverse travel (manual/auto) (Y axis) | 255/244mm |

| Vertical travel (manual/auto) (Z axis) | 320/300mm |

| Cutting feed speed | X,Y:23.5-1180,Z:8-394mm/min |

| Rapid feed speed | X:2300,Y:2300,Z:770mm/min |

| Spindle speed range | 30-1500rpm |

| Spindle speed step | 18 |

| Distance from table center to column guideway | 215-470mm |

| Max.swivel angle of spindle | ±45° |

| Distance from spindle axis to table surface | 30-350mm |

| Spindle motor power | 7.5kw |

| Overall dimension | 2294*1770*1720mm |

| Machine weight | 2650kg |