VIDEO ABOUT HORIZONTAL MACHINING CENTER 63H

DESCRIPTION OF HORIZONTAL MACHINING CENTER 63H

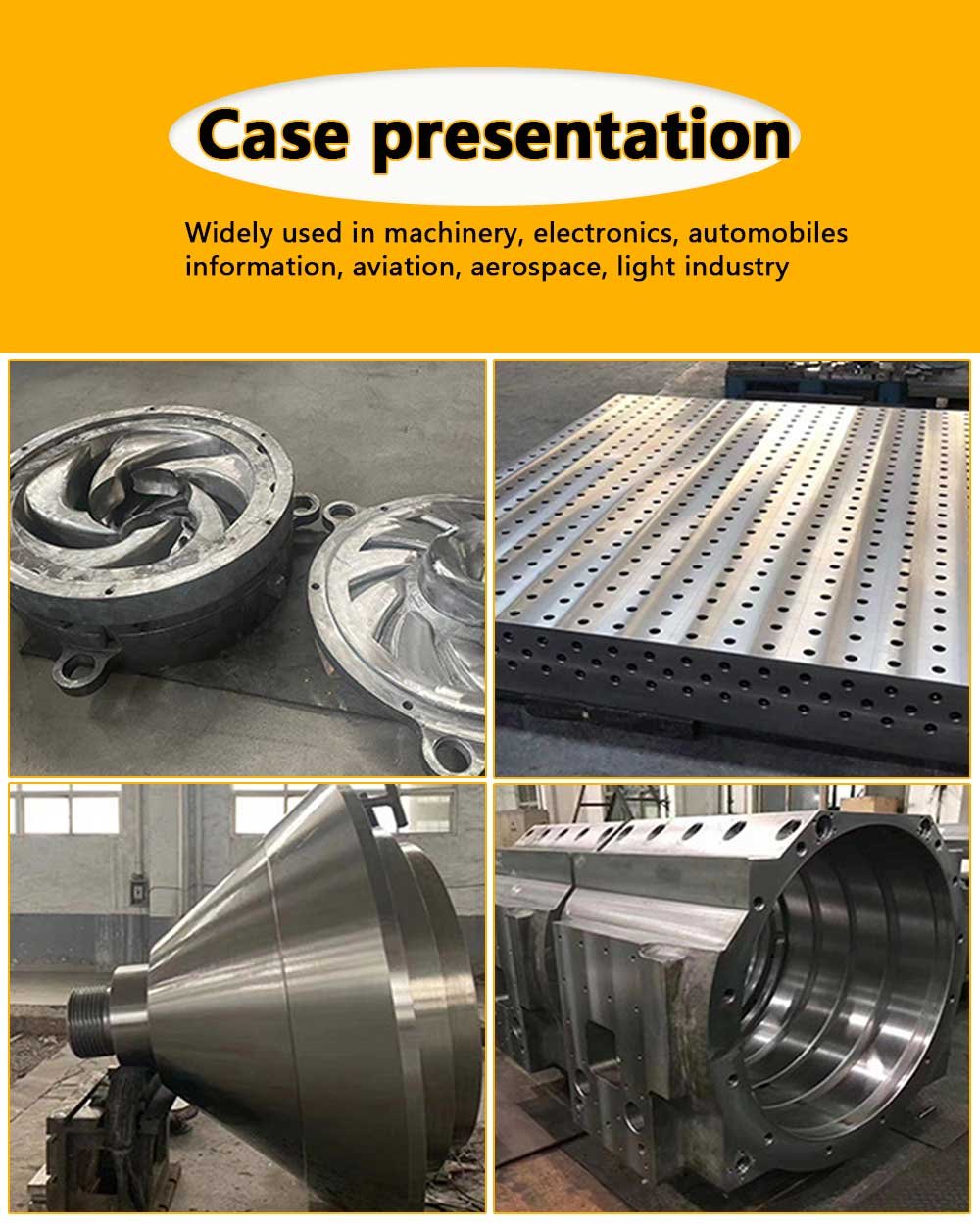

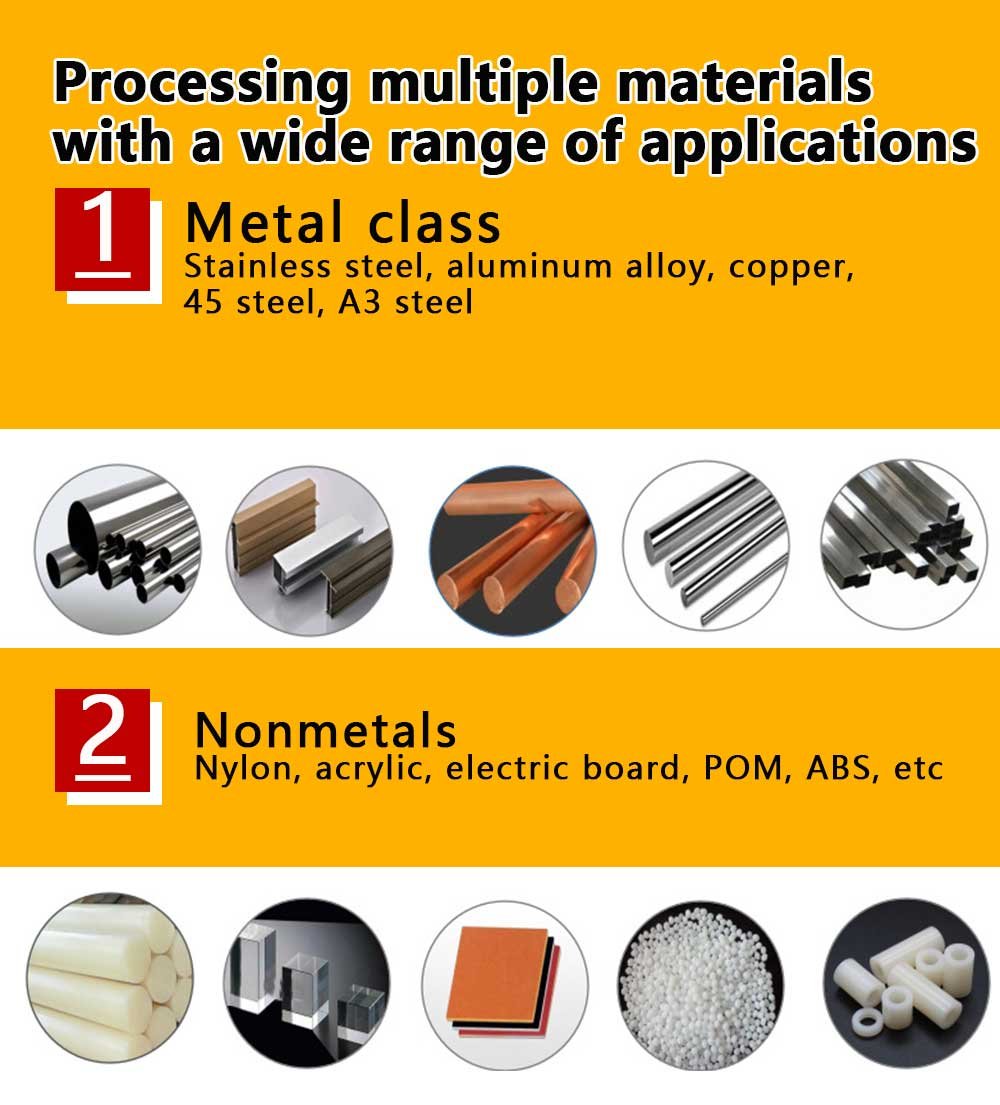

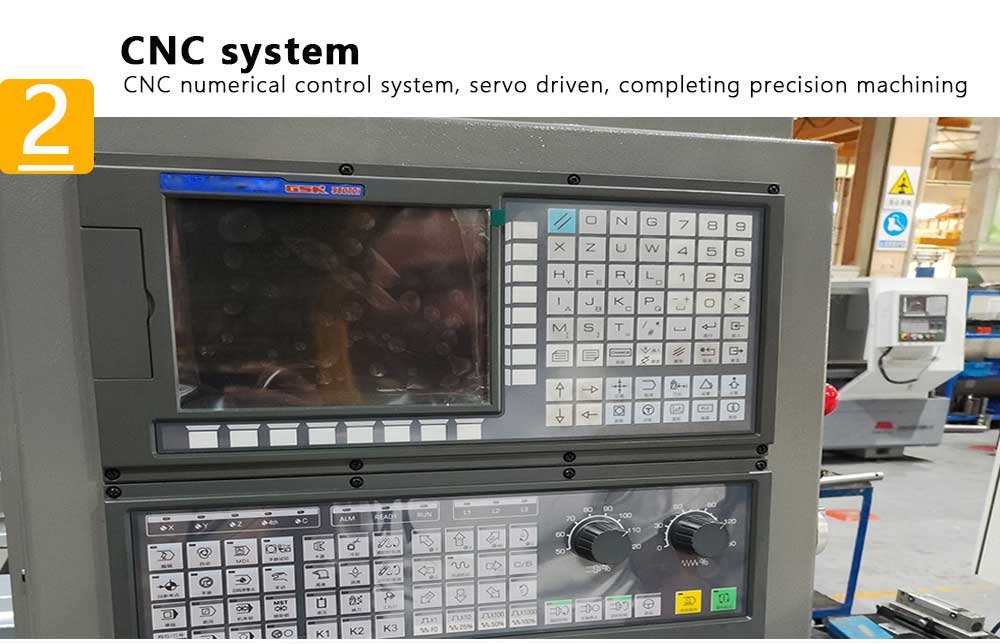

The H-series horizontal CNC machining center is a processing equipment mainly used for processing car bodies, car bodies, and formed parts. Commonly used in the production of automotive engine casings, molds, and other related parts, it is very suitable for the general machinery manufacturing industry. In the production process, first-class research and development technologies such as 3D synchronous design and finite element analysis are adopted, combined with the use of N improvements. Its reasonable layout ensures that the main components have good deformation resistance and bending performance, with ultra-high stability and accuracy.

CHARACTERISTICS OF 63H

| Model | 2010S |

|---|---|

| Table size | 2100*1000mm |

| Maximum load-bearing capacity of the workbench | 2000kg |

| X/Y/Z axis coordinate stroke | 700/1000/2000mm |

| Distance from the centerline of the spindle to the front guide rail of the column | 1050mm |

| Distance from spindle end face to workbench plane | 160-860mm |

| X/Y/Z maximum feed speed | 1-10000mm/min |

| X/Y/Z maximum movement speed | 30/30/24m/min |

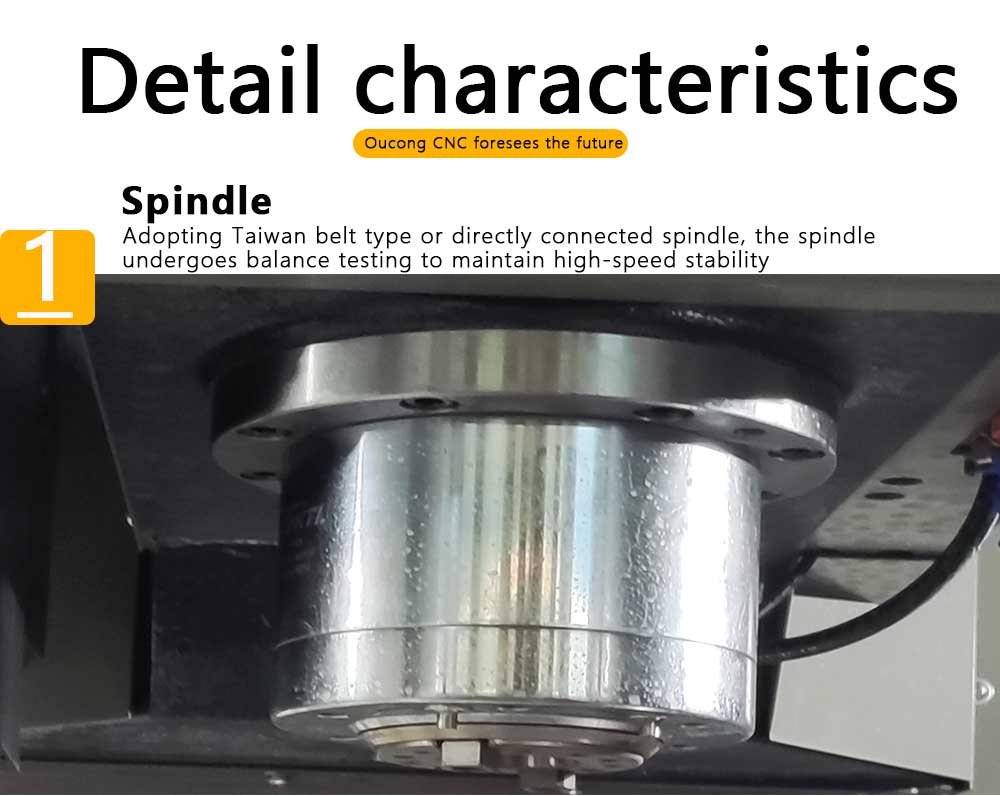

| Maximum spindle speed | 6000r/min |

| Spindle taper | BT50-155 |

| Spindle motor power | 11kw |

| T slot(number-width*pitch) | 5-22-200mm |

| Positioning accuracy | 0.008mm |

| Repetitive positioning accuracy | 0.006mm |

| Tool magazine form | Bamboo hat style (optional disc) |

| Magazine capacity | 24 |

| Overall dimension | 4800*3700*3300mm |

| Machine weight | 11000kg |