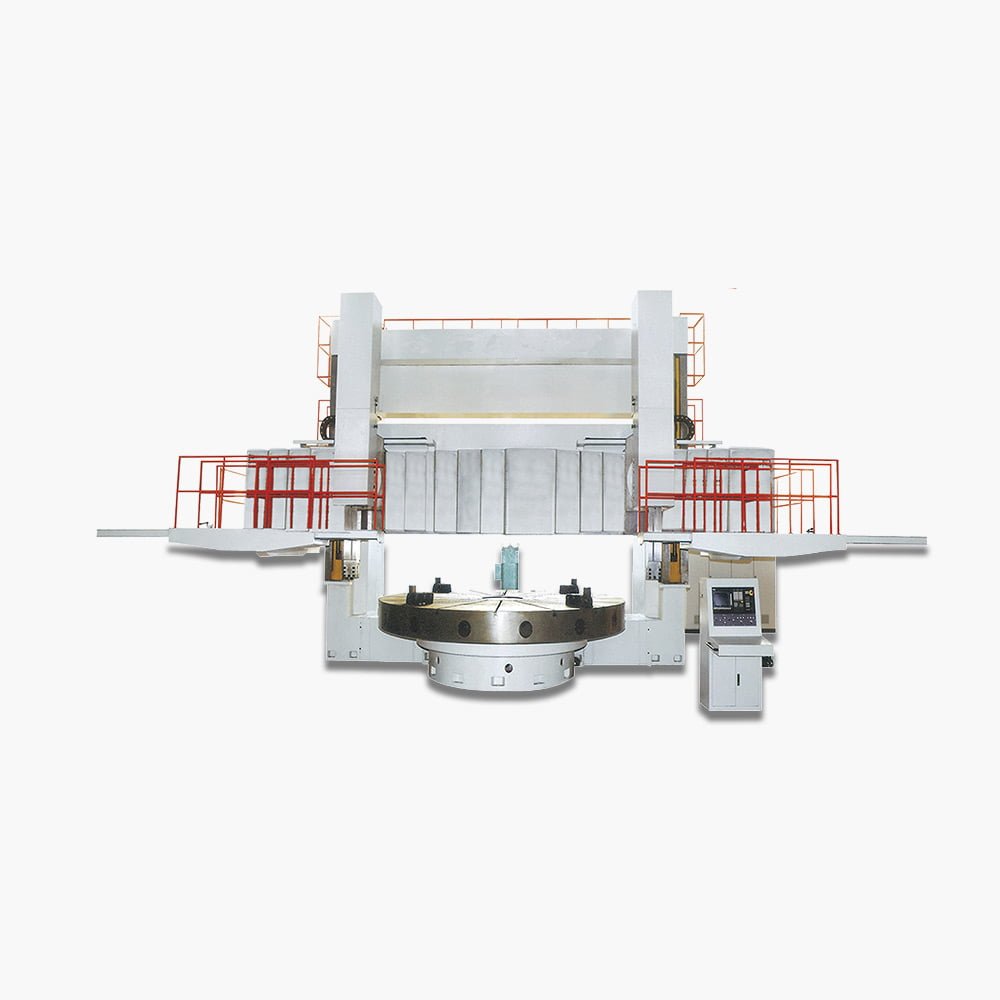

VIDEO ABOUT DOUBLE COLUMN VERTICAL LATHE MACHINE C5250

DESCRIPTION OF DOUBLE COLUMN VERTICAL LATHE MACHINE C5250

The base part of the whole cast body parts, using high strength and low stress cast iron material, annealing after casting, aging treatment after rough processing. In the guide column adopt grinding, light and RAM guide adopt after processing grinding quenching intermediate frequency.

The main gearbox is driven by an AC motor, the speed change of the main drive with 16 steps is controlled by electromagnetic valves. All gears in the gearshift housing in the cabin adopt high frequency quenching. The work table is clean and can accept sliding and static pressure in the guide rail.

Feeding horizontal and vertical vertical tool-post use ball screw driving driven by BU AC servo motor, so as to realize automation. Left and right tool – after taking the hydraulic balance by sliding the guideway in the horizontal and vertical direction, and insert the guideway high strength PTFE soft belt.

The hydraulic system is equipped with a Germany traffic transmission device, so as to guarantee the stability of the oil flow on the workbench lubrication.

The machine uses PLC control, high reliability, wiring according to the execution process.

Beautiful appearance, consistency, convenient operation and maintenance.

According to customer’s raquirement, we can provide under the action of electric drive spindle grinding cylinder head, cooling device, DRO, etc.

Equipped with a CNC system depending on the customer.

Adopt Chinese famous product quality level.

CHARACTERISTICS OF C5250

| Model | C5250 |

| Table diameter | 4500mm |

| Max.Turning diameter | 5000mm |

| Max.Height of workpiece | 2000T |

| Max.Weight of workpiece | 32mm |

| Table speed range | 16 |

| Table speed steps | 0.5~40r/min |

| Max.Ttorque of table | 70kN.m |

| Right vertical tool holder maximum cutting tool | 35kN |

| Horizontal stroke of right vertical tool holder | -50~2770mm |

| Right ram vertical travel | 1250mm |

| Right vertical tool rest feed range | 0.2-145mm/min |

| Maximum cutting force of left vertical tool holder | 30kN |

| Left vertical tool holder horizontal stroke | -50~2770mm |

| Left ram vertical travel | 1250mm |

| Left vertical tool rest feed range | 0.2-145mm/min |

| Vertical tool holder mobility limit | ’-15°~+30° |

| Section of ram | 240x240mm |

| Knife bar section | 50x50mm |

| Vertical tool holder fast movement speed | 1550mm/min |

| Max.Travel of cross beam | 1650mm |

| Cross beam lifting speed | 310mm/min |

| Cross beam lifting motor power | 15kw |

| Main motor power | AC70kw |

| Machine weight | 64000kg |

| Overall dimension | 9200*5800*5800mm |