VIDEO ABOUT CNC LATHE WITH INCLINED BED TCK 50

DESCRIPTION OF CNC LATHE WITH INCLINED BED TCK 50

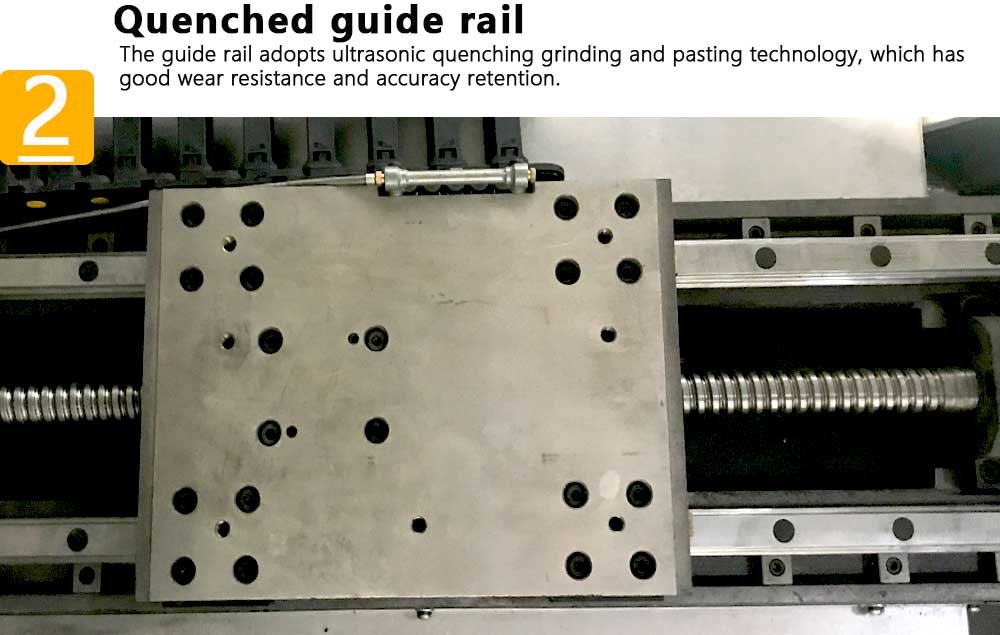

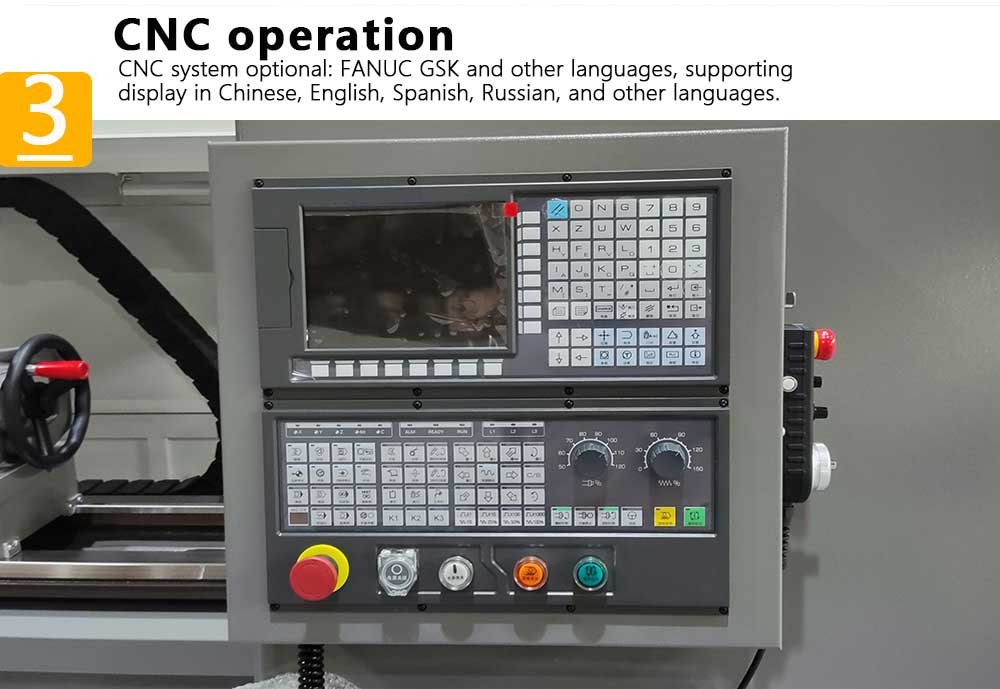

The machine model TCK50 is a fully functional turning machining center with numerical control, developed and designed using advanced foreign technologies. The design and controls are designed to meet the requirements of ergonomics: it is convenient and easy to operate. This machine is designed to perform turning operations of finishing and semi-finishing, including the processing of cast iron castings, due to the use of a high-speed spindle. Movements along the axes occur along high-precision rolling guides of the HGH35 series, resistant to vibration. They have high rigidity and allow turning with the removal of large allowances. In the presence of appropriate software (CAD /CAM systems) – the key to the efficient operation of CNC machines – the reconfiguration of the machine by a process engineer takes minimal time. You just need to change the program, which reduces the complexity of changeover by 80-90% compared to the complexity of this operation on manually operated machines and ensures the individuality of any complex part. The machines are manufactured according to the GB/T 16462.1-2007 precision standard.

CHARACTERISTICS OF TCK50

| Model | TCK50 |

| Swing over bed | 560mm |

| Swing over cross slide | 260mm |

| Distance between centers | 350/500/800mm |

| Spindle bore | 66/66/86mm |

| Spindle nose type | A2-6/8 |

| Spindle speed range | 0-3000rpm |

| Turret/tool post | Horizontal 8/12 workstation |

| Tool size | 25*25mm |

| X axis travel | 240mm |

| Z axis travel | 400/540/900mm |

| X axis rapid traverse | 24000mm/min |

| Z axis rapid traverse | 24000mm/min |

| Main spindle motor | 11/11/15kw |

| Guide rail type | Linear guide rail |

| Machine weight | 3200/3600/4500kg |

| Overall dimension | 2700/2700/3300*2000*2000mm |