DESCRIPTION OF SINGLE COLUMN HYDRAULIC PRESS YQ41-160

1.Thanks to the intelligent design, the single-frame structure with a central manipulator has the characteristics of reliability, simplicity of design and ease of operation.

2.The frame is fully welded to the steel plates and undergoes hardening pressure.

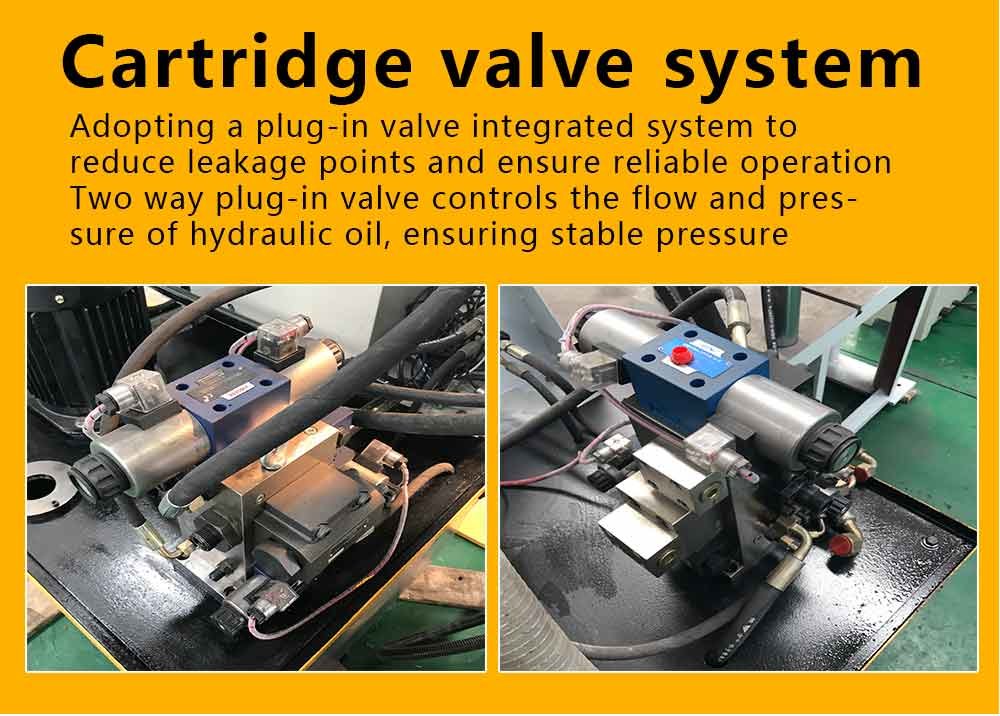

3.Cartridge valves equipped with hydraulic control system are reliable, durable, the hydraulic impact is small, the connecting tube is shorter, and the outlet point is smaller.

4. The hydraulic system uses a pre-pressurization device, and the water pressure is low.

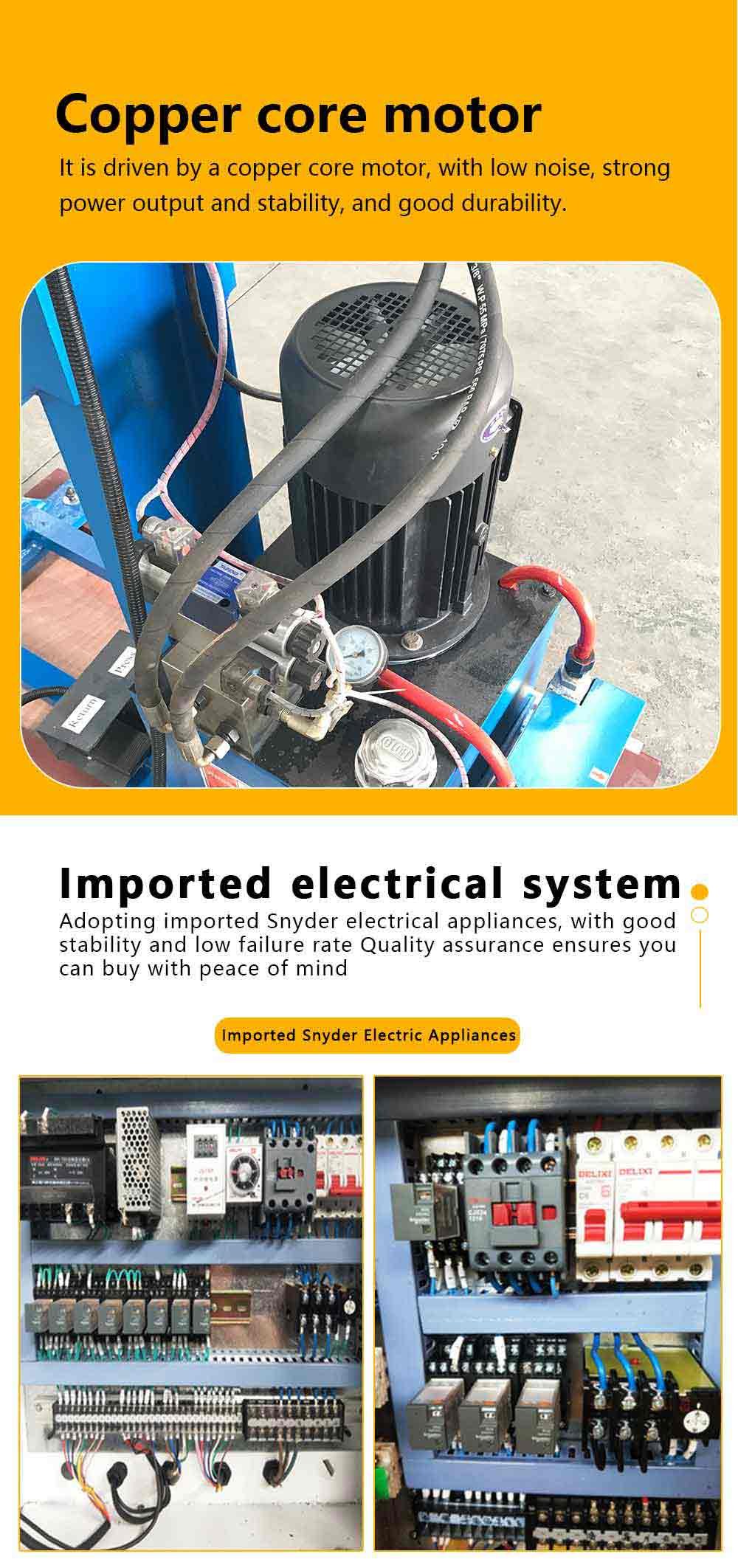

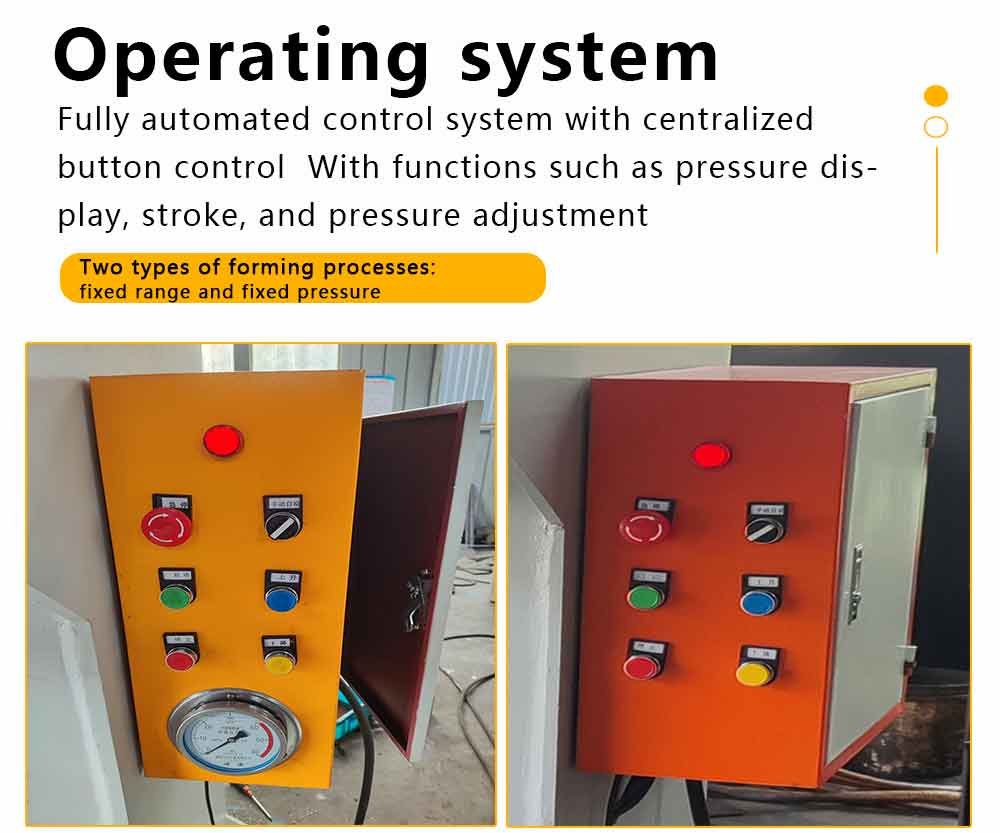

5. Independent electrical control, reliable, audiovisual, easy to maintain.

6.The centralized push-button control system has a manual and semi-automatic operation mode when selecting operators (semi-automatic mode has two types of technology: The positioning stroke order and the positioning pressure list).

7. Working force, no-load movement and low-speed movement, as well as the stroke range can be adjusted according to technical requirements.

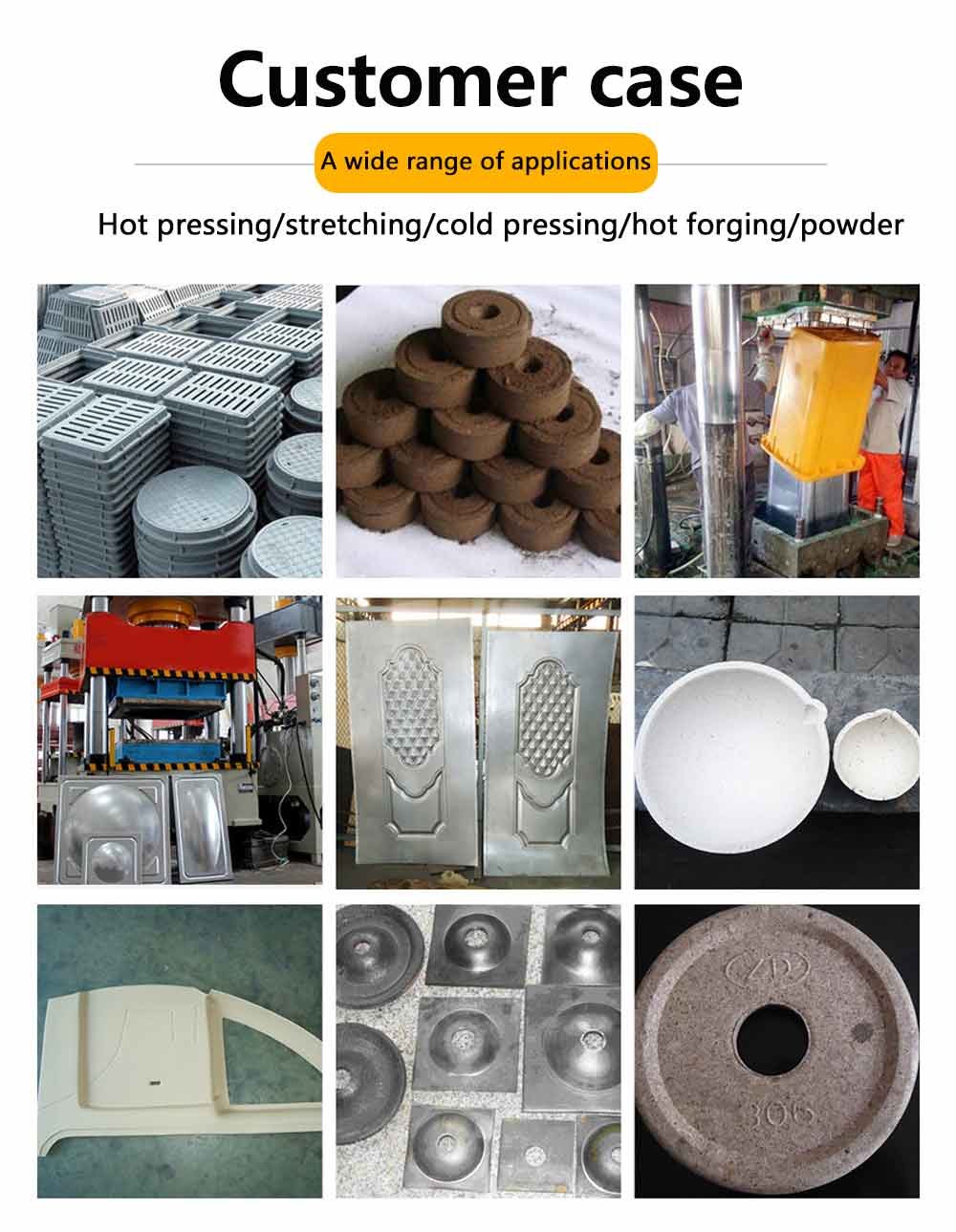

The machine is suitable for shaft parts, bearings and other parts of the calibration process, can also be applied to shaft sleeve and sleeve parts, can use a simple strip shape assembly stretching, forming, stamping, stamping processing;

The use of manual and foot lever mechanism, easy operation, low power consumption, low noise can lead to the serial production of the tonnage machine according to customer requirements.

CHARACTERISTICS OF YQ 41-160

| Model | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

|---|---|---|---|---|---|

| Nominal force | 1600kN | 2000kN | 2500kN | 3150kN | 5000kN |

| Piston stroke of the working cylinder | 360mm | 400mm | 400mm | 500mm | 500mm |

| Maximum opening distance | 800mm | 1000mm | 1000mm | 1200mm | 1200mm |

| Throat depth | 320mm | 360mm | 420mm | 500mm | 600mm |

| The speed of the slider(working. Move) | 13 | 15 | 15 | 50 | 50 |

| The speed of the slider(return. Move) | 20 | 20 | 20 | 60 | 55 |

| Table dimensions (left to right) | 700mm | 800mm | 900mm | 1050mm | 1200mm |

| Table dimensions (front to back) | 600mm | 700mm | 800mm | 900mm | 1050mm |

| Diameter of the plug hole | 200mm | 220mm | 220mm | 240mm | 240mm |

| Overall dimensions | 1450*800*2240mm | 1850*990*2450mm | 1980*1090*2580mm | 2150*1040*3420mm | 2300*1280*3640mm |

How to choose a suitable hydraulic press for you?

<Eight Elements of Choosing a Hydraulic Press>

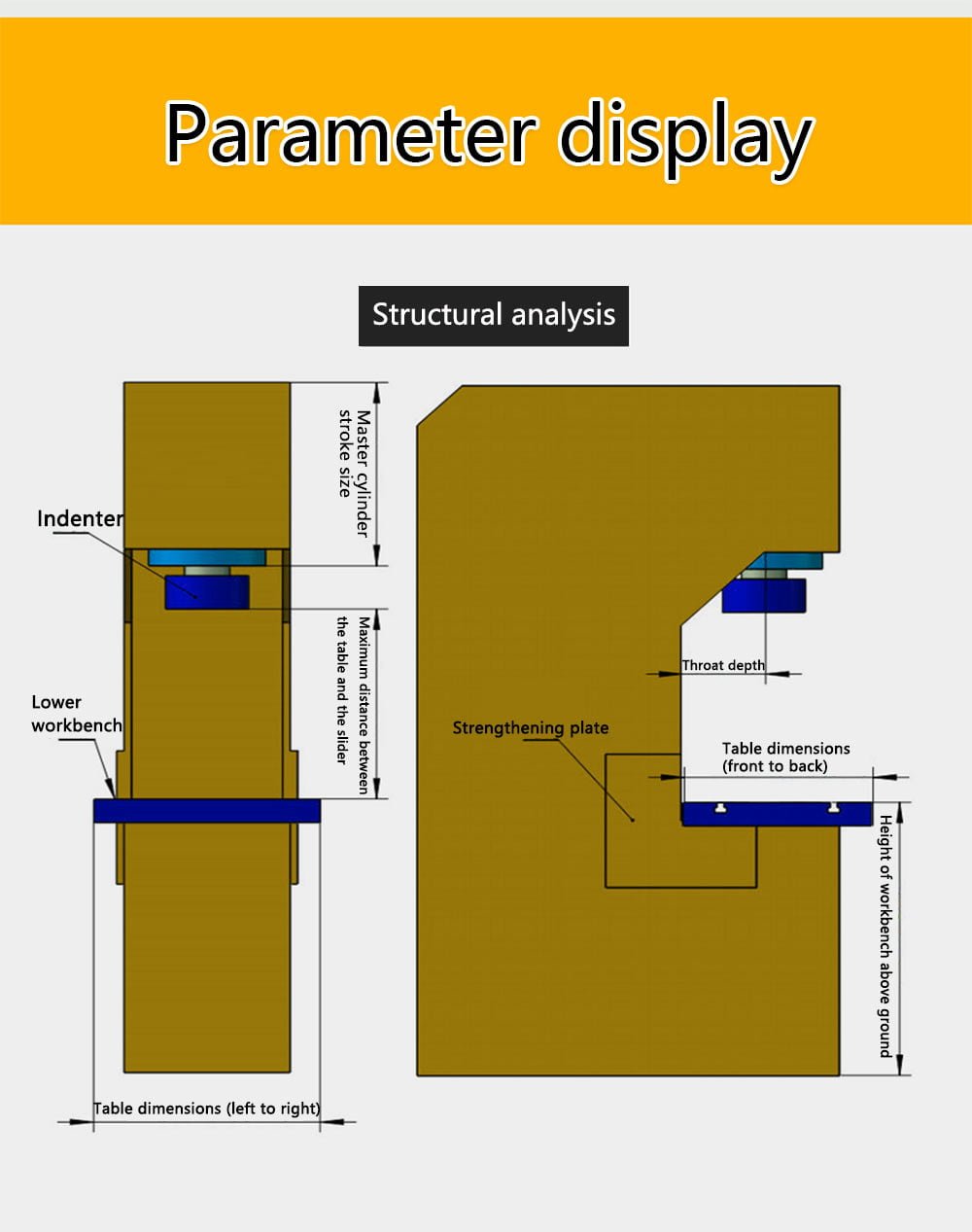

1、 Workbench size

The effective dimensions of the hydraulic press are: the distance between the left and right sides, and the distance between the front and back edges. The size of the workbench is determined based on the external dimensions of different products (molds). When a hydraulic press simultaneously presses (stretches) different sizes, it is determined based on the maximum size of the product (mold). In theory, the size of the product (mold) accounts for 70% -80% of the effective size of the workbench, and the specific situation is according to customer requirements.

2.Distance between the table and the slider

The opening size refers to the maximum distance from the top of the oil cylinder to the workbench. According to the different pressing (stretching) distances of different products, in order to maximize cost savings, it is sufficient to ensure a safety margin of 50MM-100MM remaining in the main cylinder of the pressing (stretching) product. It is also important to consider making it easier to remove the product after mold opening.

3、 Master cylinder stroke

The main cylinder stroke refers to the range of piston rod stroke, which should be less than the maximum stroke of the main cylinder to prevent damage to the cylinder.

4、 Mold height

The clamping height refers to the maximum opening height minus the stroke of the main cylinder. The clamping height should be less than the height of the product (mold) after molding. For example, if the opening height is 900MM, the stroke of the main cylinder is 600MM, and the clamping height is 300MM, that is, the height of the product (mold) should be greater than 300MM.

5、 Height of workbench above ground

Normal 600MM-750MM, with different requirements for different processes, the height above the ground plus the height of the product (mold) ensures safe and comfortable operation for workers.

6、 Working speed

The speed of hydraulic presses can be divided into slow, fast, and high-speed. The selection of speed depends on the product process.

7、 Action requirements

The actions are divided into: pressing and stretching, stretching products, and demolding processes, which require the installation of a top cylinder. The operation methods are divided into manual and automatic.

8、 Throat depth dimension

The throat depth dimension refers to the distance from the middle point of the hydraulic cylinder to the wall panel. The throat depth dimension is determined based on the size of the product (mold), and should be greater than the radius of the product (mold) to ensure that the center point of the product (mold) is perpendicular to the center point of the hydraulic cylinder when working on the hydraulic press workbench.