VIDEO ABOUT VERTICAL SLOTTING MACHINE 7A432

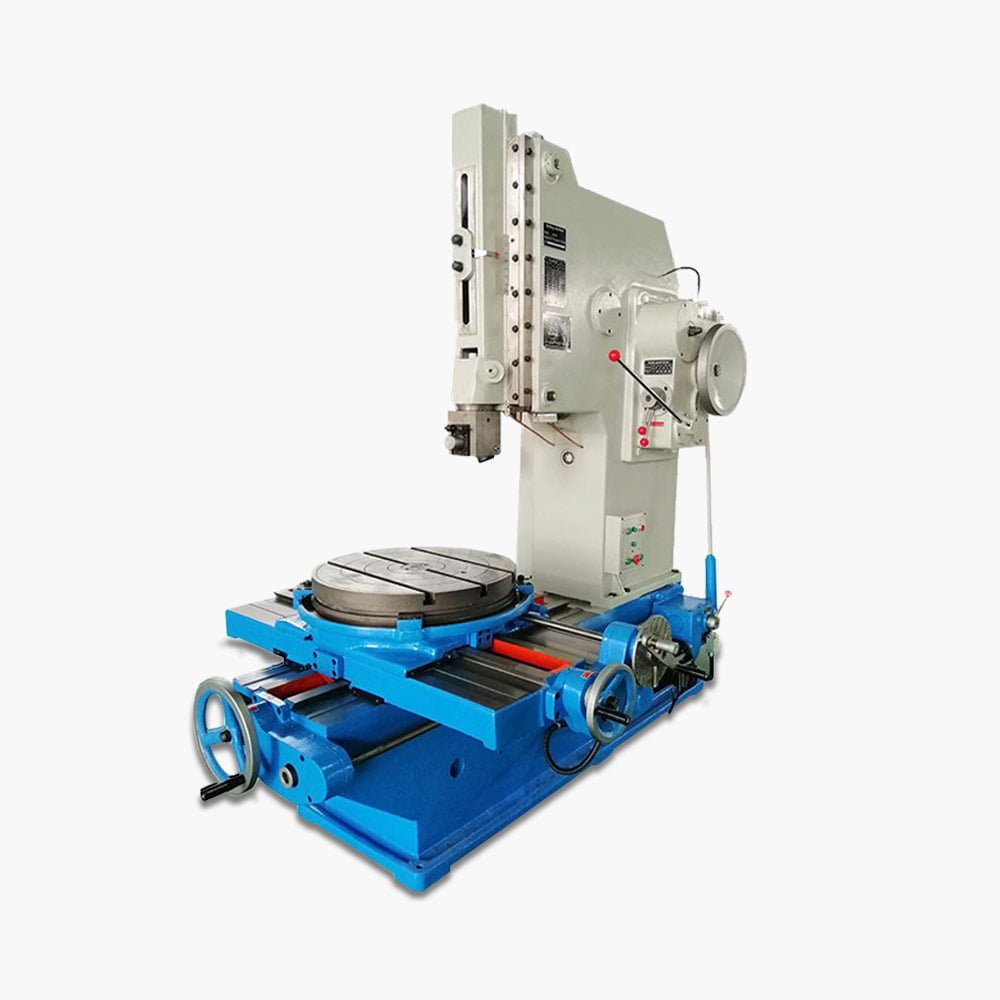

DESCRIPTION OF VERTICAL SLOTTING MACHINE 7A432

The purpose of the 7A432 rock drill is to use chiseling and irregular straight external surfaces and holes, as well as chiseling various shapes of grooves and grooves in parts manufacturing, instrument manufacturing, machine tool manufacturing, and other industries. On this type of rock drill, metal and non-metallic products, such as plastic products, can be processed.

CHARACRISTICS OF 7A432

| Model | 7A432 |

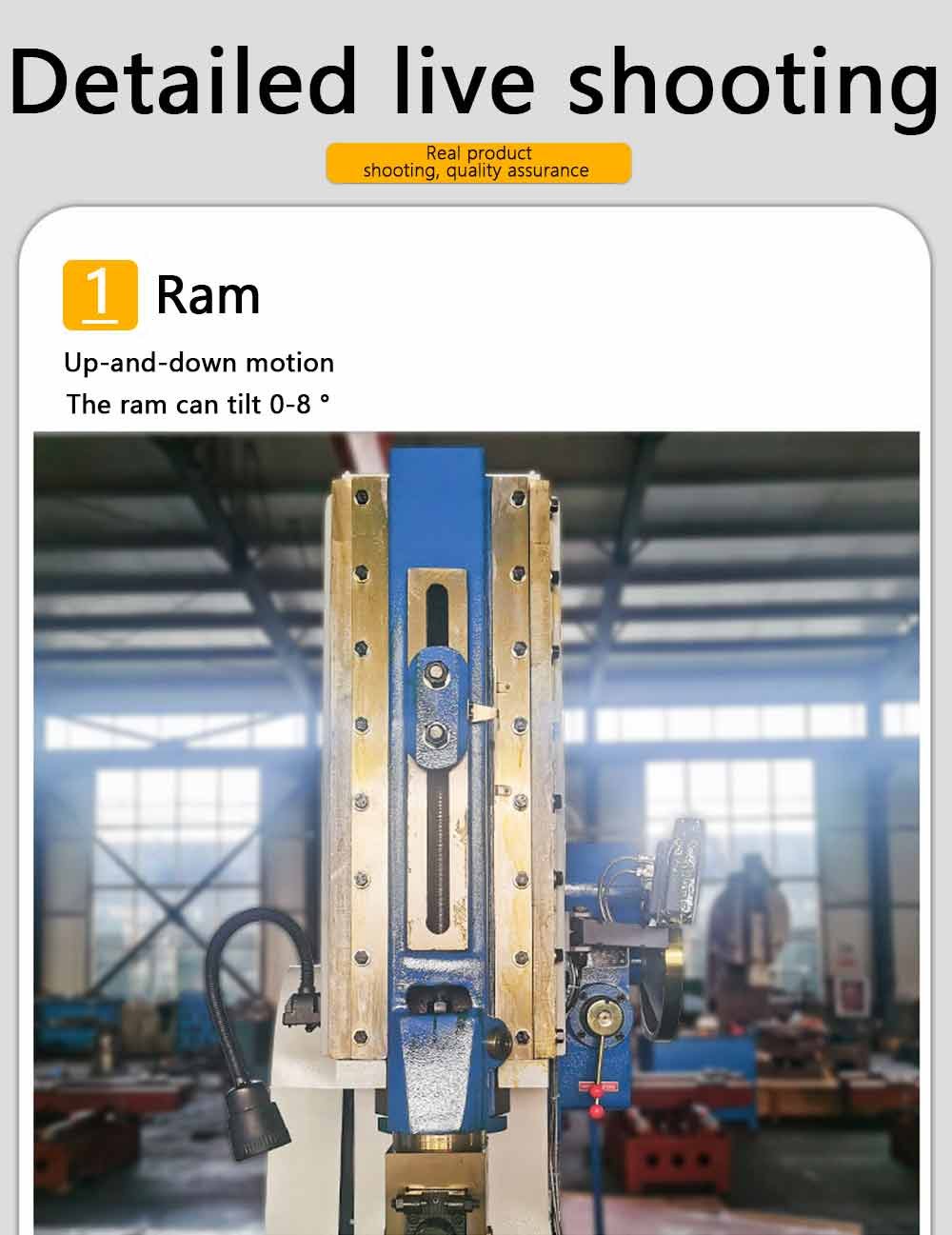

| Maximum stroke of the ram | 340mm |

| Maximum pin length | 320mm |

| Workpiece processing size (L × W) | 600×320mm |

| Workpiece weight | 500kg |

| Maximum cutting force | 7500N |

| The number of strokes per minute of the ram | 20.32.50.80.r.p.m |

| Vertical adjustment distance of the ram | 315mm |

| Slide tilt angle | 0-8° |

| Distance between the support surface of the cutting head and the front wall of the bed | 600mm |

| Insertion tool size (L × W) | 25×40mm |

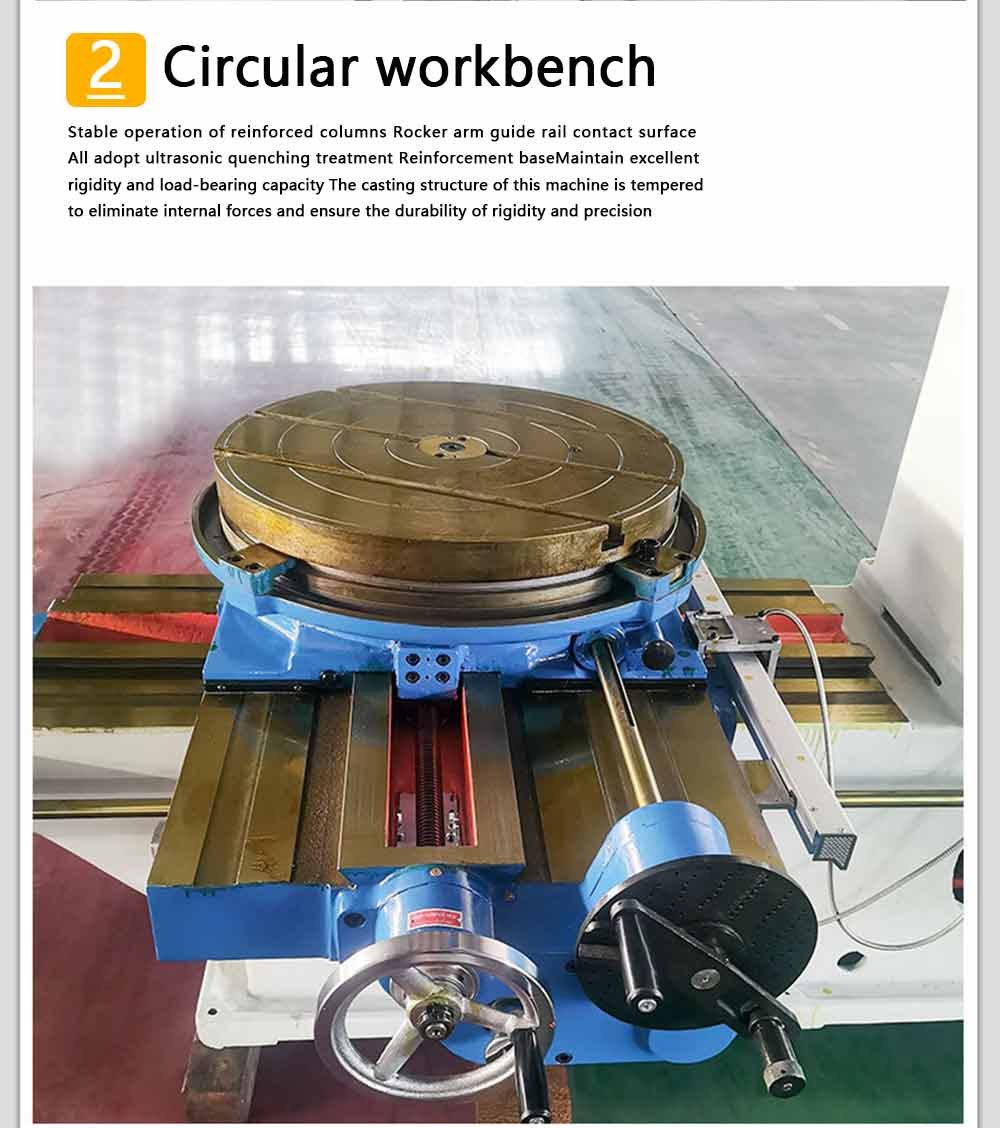

| Workbench diameter | 630mm |

| Distance between workbench and lower end of sliding frame | 490mm |

| Longitudinal movement distance of workbench | 480/620mm |

| Horizontal movement distance of workbench | 480/560mm |

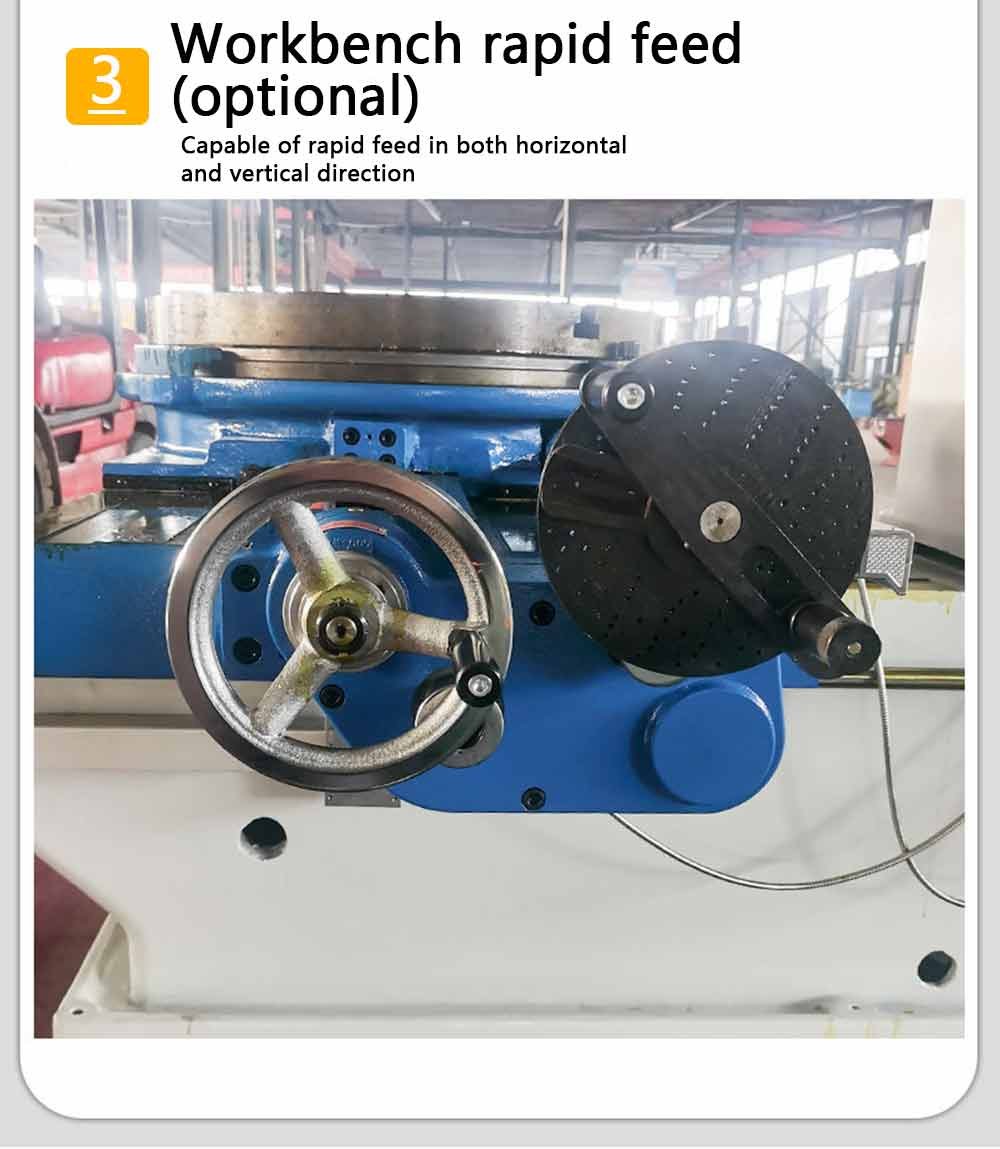

| Working table vertical and horizontal motorized feed range | 0.08-1.21mm |

| Rotary feed range of workbench | 0.052-0.783mm |

| Main engine power | 4KW |

| Outline dimensions of the slotting machine (L × W × H) | 2261×1495×2245mm |

| Machine tool quality | 3000kg |